Descrição

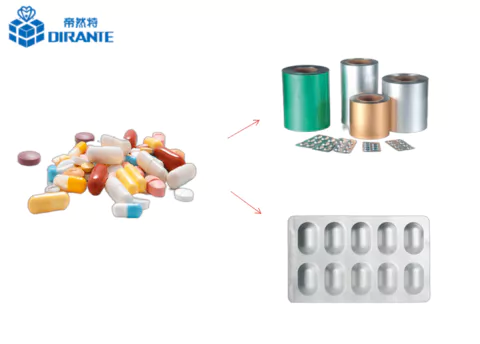

Folha sanduíche de OPA/Al/PVC sanduíche de AVC para pacotes de bolhas Sobre a Folha de Alu Alu Alu Alu, formada a frio: A folha de alumínio formada a frio está no coração das folhas de sanduíche alu alu OPA/Al/PVC usadas para aplicações de pacotes de bolhas farmacêuticas devido às suas vantagens inerentemente superiores. O alumínio, mesmo na espessura dos micron, é a melhor barreira de vapor e luz, além de proporcionar brilho estético para embalagens de bolhas farmacêuticas. Nome Folhas de alumínio de forma fria Estrutura NY25/AL45/PVC60 NY30/AL60/PVC60 GSM 240g 281g Largura de especificação 1000mm; Thickness: 0.14-0.16 mm; ID of core: 76 mm OD of core: 240-280mm, also can be according to customer’s requirements There are regulations on how moisture-, oxygen- and light-resistant blister packaging must be, but some products may require extra resistance. While many different materials can be used to make blister packs, they can be separated into two categories: cold-formable and thermoformable; Cold-formable material is commonly pressed aluminum that is laminated with plastic. The aluminum is resistant to many outside forces and has high mechanical resistance; aluminum has a tendency to leech into other materials and to crack, but the plastic inclusion corrects these issues. Thermoformable materials are plastics that can be easily molded into any shape, but they are not as resistant to outside forces — especially light — because the plastic is transparent. If the product is a simple shape that needs high resistance, then cold-formable materials are likely best; Cold Forming Blister Foil(Alu-Alu) is one kind of blister primary packaging material for solid pharmaceuticals, like tablet & capsule. The foil produced in Dirante factory is three layers laminated: oPA / Alu / PVC, under using dry bond lamination technology. Cold Forming Blister Foil Structure: Cold Forming Blister Foil Features 100 % barrier against water vapor, gases, light etc. Excellent formability High degree of thermal stability High malleability for deep drawing blister cavities High aesthetic appeal Sealable with aluminum lidding foil Colorful surface as RAL color-list The PVC film in alu -alu laminate is commonly used as the contact layer and seal to the lidding foil on pharmaceutical blisterpack (as neutral layer for the goods to be filled). PVC is very stiff and does not tend to shrink or spring during cold forming. Once the cold forming process is complete, the PVC helps the cavity hold its shape. In short, it ensures the geometric stability after cold forming. The nylon (oPA) film is mostly responsible for the multi - axial forming. Laminating the aluminum with the oPA film doubles the formability of the blister. Cold Forming Blister Foil Specification Name Cold-Form Aluminum Foils Structure oPA 25-30 mic/ Alu 45-75 mic/ PVC 60 mic Specification Width: 60 - 1000 mm; Thickness: 130 - 200 mic; Core ID: 76 mm, paper reel; Roll OD: 260-300mm, also can be as your request>

- Alu Alu

- Fundo

- Folha

- Prata

- Comprimidos

- Composto

- Bolha

- Folha

- Laminado

Capacidade de produção:

2000

Prazo de Entrega:

Em 45 Dias

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Informações da Embalagem:

Cardboard box fumigated pallet

Mais sobre a

Cold Forming Foil &PTP Blister Foil

50-100

Funcionários

200K - 500K

Volume de vendas (USD)

50%

% Vendas com exportação

Ano

Ano de Fundação

Tipo de negócio

- Fabricante

Palavras chaves

- Farmacêutico

- primário

- embalagem

- materiais

- alumínio

- bolha

- folha Ver Mais

Contato e localização

-

Alaia ********

-

+86 18********

-

LUOYANG / HENAN | China